pressure testing hydraulic systems|hydraulic pressure testing pdf : supplier The Testing and Flushing Hydraulic Power Unit (TFHPU) is designed to supply low & high pressure tap water or water/glycol fluids for use in hydrostatic testing, flushing and general hydraulic applications. Testing system is rated to 1380 . Catarina Paulino 😏🔥 BR_92. 3212,3K. Catarina Paulino Roludo66. catarina. Catarina Paulino photos & videos. EroMe is the best place to share your erotic pics and porn videos. .

{plog:ftitle_list}

WEBA SPORT TV transformou-se em poucos anos num império da comunicação social de cariz desportivo em Portugal detendo os direitos de transmissão da LIGA PORTUGUESA e .

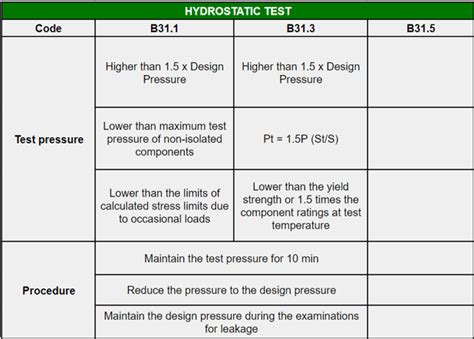

Pressure testing is an important safety process that ensures your hydraulic systems operate safely, optimally, and efficiently. Through hydraulic pressure testing, you can determine the minimum and maximum operating pressure.The Testing and Flushing Hydraulic Power Unit (TFHPU) is designed to supply low & high pressure tap water or water/glycol fluids for use in hydrostatic testing, flushing and general hydraulic applications. Testing system is rated to 1380 .SHS utilizes the HiP T-Series pump within their system design to ensure pressure requirements are met and the testing process can run its course without loss. An example of a circuit diagram for a test unit for this application .Over Pressurizing a System – To avoid over pressurizing a system the test pressure has to be established. The engineer or other qualified person who will make that determination needs to know the design pressures for each component in the piping system such as gauges, valves, fittings, etc. that will be included in the test. , Design .

Robust hydraulics services include burst and proof pressure testing, continuous flow, performance verification, pressure drop testing, leakage, impulse, pressure cycling, endurance testing, and more. . Some of the most common applications of hydraulic systems are in heavy construction and off-highway equipment. Other applications can be seen . When a low-pressure component is mistakenly connected to a high-pressure system, it can lead to catastrophic failures, including hose blowouts or sudden releases of pressurized fluid. To prevent such hazards, you'll need to ensure that couplings are properly matched and rated for the specific pressure requirements of the hydraulic system .

Safely pressure testing piping systems is challenging at times, but it can be accomplished with minimal risk to workers. The key to safe pressure testing is knowing the potential hazards and understanding how to eliminate or minimize them as much as possible.The two main factors which affect the flow of fluids are pressure and density, so these concepts are also fundamental to the study of hydraulics. In this article, we will consider the key concepts of pressure and flow and how they apply to hydraulic systems – as it is the pressure and flow which enable work and motion to be accomplished.

core test vs core hard extreme

Hydrostatic tester. A hydrostatic test is a way in which pressure vessels such as pipelines, plumbing, gas cylinders, boilers and fuel tanks can be tested for strength and leaks. The test involves filling the vessel or pipe system with a liquid, usually water, which may be dyed to aid in visual leak detection, and pressurization of the vessel to the specified test pressure.When using pressure systems every employer or self-employed person has a duty to provide a safe workplace and safe work equipment. Designers, manufacturers, suppliers, installers, users and owners have additional health and safety duties. Learn more and watch along in the video at the end of this post as we explain our hydraulic pressure testing process. Why Pressure Test a Cylinder The ability to hold pressure is paramount to the action of a hydraulic cylinder and an inability to hold pressure is a clear sign of failing conditions in seals, other parts, and even the cylinder .Flushing and pressure testing – Chapter 3 Flushing is a critical step in the hydraulic piping procedure as it ensures the cleanliness of the piping. Given the variety of hydraulic systems, it is important that the relevant professionals are present at a very early stage to set the right goals for the level of purity.

To properly use the results of a pressure test it is best to first understand the pressures generated during different types of braking and the function of the different brake valves used in the system.You will need to obtain a brake hydraulic pressure test kit similar to the image aboveBecause most manufacturers do noTEST PAC 33 • 1/3rd HP output with test pressures up to 1,000 bar with oil, 700 bar with water • Typical flow rate up to 6 litre/min for low pressure units down to 0.2 litres/min for 1,000 bar unit • Supplied with 4 litre polyethylene tank • Removable hand pump can be used with this system when compressed air is not available. It also allows for finer control for calibration work. Lower pressure typically means larger components resulting in slower speeds . Important Reminders. When working with components in a hydraulic system always be aware of the pressure rating of the components. If the system will operate at 2500 PSI the relief will need to be set higher, 2650-2800 PSI.Custom hydrostatic pressure test systems are our specialty. With a team of expert engineers who are experienced and innovative when it comes to designing and building hydrostatic test systems, you can trust Pneumatic and .

Hydrostatic testing can be defined as the process of subjecting a material to a controlled pressure and observing how it reacts to the pressure. The test is used for many reasons: determining if an object will withstand various loads or .

Hydraulic Systems 9 Toro University Technical Training Understanding the basic hydraulic systems and components can be of great value when troubleshooting and testing hydraulic equipment. The upper illustration would be a circuit used to raise a cutting unit with a hydraulic cylinder. The lower

Identification of the piping system; Test fluid used; Test pressure was applied, and; Certification of the results by the examiner. Keeping accurate records is crucial for documentation, compliance, and reference purposes. What Are The Preparation Steps for Pressure Testing. The preparation steps for pressure testing involve the following: 1.Pneumatic & Hydraulic Company is a premier supplier of pneumatics, hydraulics, filtration and motion control products. For more than 60 years, we have provided a comprehensive line of pneumatic and hydraulic products backed by strong, personal customer service. . Our automated high pressure testing systems, including pressure testing chambers .Quiz yourself with questions and answers for Suspension and Steering II - AUT 204 - Chapter 122 - Hydraulic Power Steering Systems - Chapter Quiz Questions, so you can be ready for test day. . When pressure testing a hydraulic assisted power steering system, the highest pressures were greater than 50 PSI of each other. This indicates a .Hydraulic pressure relief valves are available in almost 100% all hydraulic systems, so it is important to have a full and deep understanding of the characteristics of the relief valve used, read more about the pressure relief valve type, function and its tested method.

ASME B31.3 requires leak testing of all piping systems other than Category D systems. For piping in Category D Fluid Service, the piping may (at the Owner's option) be put in service without a leak test and examined for leakage during the initial operation of the system. This is an initial service leak test.

Monitor and control pressure in portable HVAC systems, hydraulics, and oil and gas equipment. Unlike other pressure transmitters that measure the difference between your system and the atmosphere, these transmitters give measurements relative to zero pressure— regardless of altitude or temperature.56679 PRESSURE TEST KIT Lit. No. 56692, Rev. 01 2 June 1, 2016 • Vehicle battery connections are clean and tight and charging system is in good condition. • Hydraulic reservoir is fi lled to recommended fl uid level. • Inspect all hydraulic fi ttings and hoses for leaks. IF TESTING A CENTRAL HYDRAULIC SYSTEM, VERIFY THE FOLLOWING: But remember, DIRT IS THE WORST ENEMY OF A HYDRAULIC SYSTEM. Before disconnecting oil lines, steam clean the machine. And be sure to plug all openings to keep out the dirt. 3. Pump Testing. The pump is the generating force for the whole hydraulic system. This is the place to start testing the system. Installing the Hydraulic Tester • Relieve .

What Is Hydraulic Pressure Testing? A hydraulic pressure test, or hydrostatic test, measures the strength of a pressure system and checks for leaks. It is performed on components such as motors, pumps, valves, actuators, hoses, tubing, and fittings. A hydraulic system may be evaluated in different ways.

Hydraulic system & components testing pressure reading data storage logger. Hydraulic systems generate a large force which is are used to move, lift, break or crush objects. Testing hydraulic systems and components is carried out on regular basis to check compliance with reliability, performance and safety requirements.

hydrostatic test pressure chart

Metadinhas♡. Bear Wallpaper. Iphone Background Wallpaper. Tumblr Wallpaper. Girl Wallpaper. Wallpaper Quotes. Boo And Sully Wallpaper. Disney Wallpaper. Sullivan Y .

pressure testing hydraulic systems|hydraulic pressure testing pdf